PUMPS, VALVES, AND TIRES; ALL YOU NEED TO KNOW ABOUT INFLATING TIRES

Pumping up the tires on your bike is an essential skill. Like other skills, you need someone to show you how; otherwise you will not know how. For our readers who do not know how (to inflate tires) do not worry. For our more experienced readers, there are plenty of fun facts to learn in this article.

Inflatable Tires

In the olden days, wheels were solid and bulky. As an improvement, pneumatic tires were invented for comfortable riding. The air within the tubes acts as a cushion, absorbing most of the shock induced by rough terrain. The treads on the rubber tires provide the necessary traction and grip; a characteristic absent in wooden and metallic wheels.

Pumping your pneumatic tires is a quick job that improves the performance and enjoyment of your bike. Before you grab your pump, you need to gain some basic knowledge on air pressure and valve types. Riding under low tire pressure exposes your tubes to the risk of snake bite punctures.

Tire Pressure

Riding on tires with too high or too low tires pressures is potentially dangerous. Tire pressure also has an effect on bike handling and performance. Running on low tire pressures exposes your bike to punctures. Low tire pressure is not enough to cushion the rim from the ground surface. When you roll over bumps, sharp edges, and potholes, the rim clinchers presses against the tubes; slicing holes at the points of contact. This type of puncture is known as the snake bite puncture. Most snake bite punctures are so severe that you may have to replace the torn tube entirely.

Riding on low tire pressure may compromise the integrity of the rim and cause dents or cracks. A bike with low tire pressure feels slow and sluggish. A lot of energy is wasted. High tire pressures exert tension on the tire, spreading out the treads and reducing grip. Tense tires are more susceptible to punctures by sharp objects. Overloading your tires with air may also build up to tire fatigue and consequently, failure.

Common Types of Valves in Bikes

The valve is the portal that allows entry of air into the tubes. It also stops air from escaping the tubes. Knowledge of valves is essential to learning the skill of inflating tires.

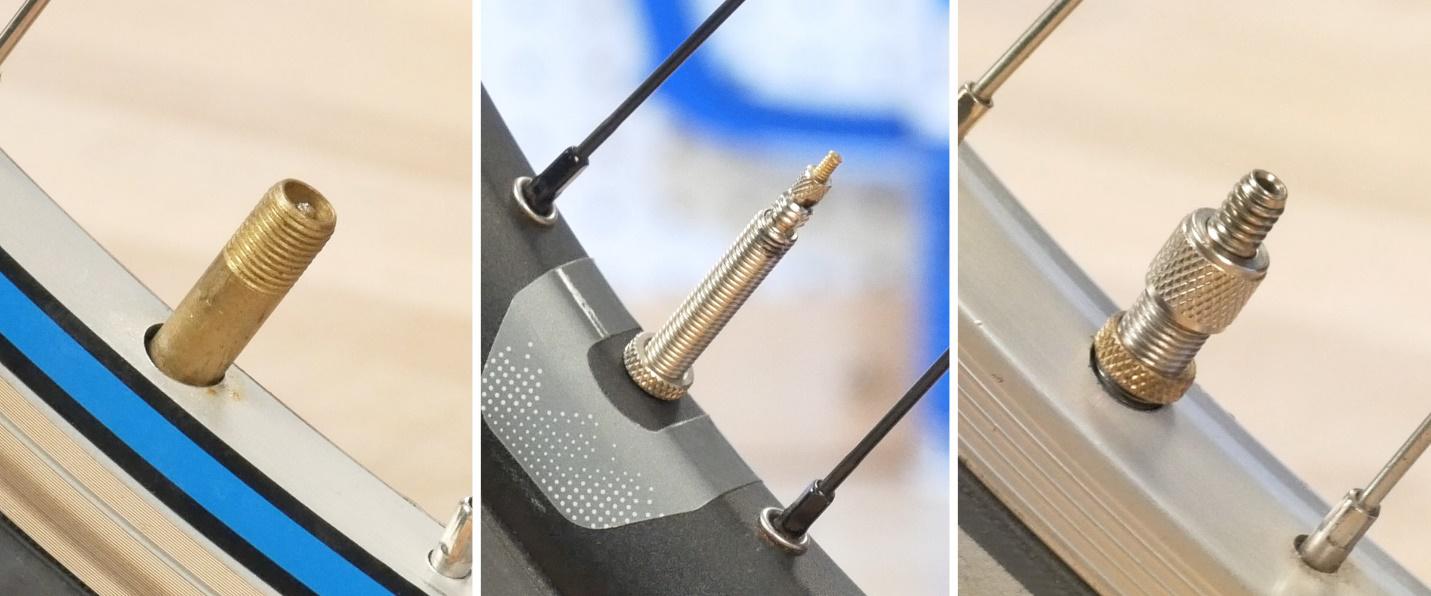

- Schrader valve: Similar to the kind of valve found in car tires, the Schrader valve assembly features a spring that opens and closes the valve automatically. The Schrader valve has a dust cap that closes the valve almost to air-tight standards. This cap acts as a backup seal should air leak out of the valve.

- Presta valve: This valve was originally designed for road bikes. It is a slender and narrow valve. These days, you may find Presta valves in mountain bikes and hybrids. To deflate a Presta valve, you need to unscrew the locknut. These valves come with a lock ring that secures the valve against the rim and a dust cup that protects the valve from dirt.

- The Dunlop or Woods valve: This valve has the same type of pump fitting as a Presta valve and a similar base diameter as the Schrader valve

- Tubeless valve: They share the resemblance of Presta valves except for the fact that they are attached directly to the rim.

From Left to Right: Schrader Valve, Presta Valve, and Dunlop/Woods Valve

Types of Bicycle Pumps

A pump inflates tires with a series of down strokes. With every downstroke, the air unlocks the pressure unlocks the valve at the beginning of each down stroke and locks it at the end of the downstroke. Types of bicycle pumps include track pumps, mini pumps, and CO2 Inflators. Bicycle pumps do the same job; others are sleeker than others. Other pumps come with attachments like pressure meters while other pumps do not have hoses. Your choice depends on your taste.

How to Inflate a Bicycle Tire

First, unscrew and remove the dust cap from the valve then check if there is any visible dirt on the valve. For Presta valves, unscrew the locknut before you attach a pump adaptor. Clean the valve if necessary, then attach the pump’s hose to the valve, push it on then lock it. For Presta valves, the lock ring on the assembly may help you secure the valve onto the pump.

Try a few down strokes to make sure that the attachment is airtight. An airtight connection sounds like a quiet hiss. If the hiss is loud, detach and reattach the valve to the pump. Whatever you do, be gentle. Valves are very delicate. A broken valve may mean buying a new tube or a new tubeless tire.

Start pumping with full strokes as you fill the tire. Push the air until you fill it moving into the tubes. For track pumps, use your body weight to push air into the tire. This technique will save you a lot of energy.

When should you stop pumping? What is the correct tire pressure for a bike? Tire pressure depends on the type of tire. A wider tire requires less pressure than thinner equivalents. A mountain bike tire requires about 25 PSI while a road bike needs between 85-110 PSI. For accuracy, refer to the writings on the side of the tire for the correct tire pressure requirements.

Pumping Road Bike Tire

If your pump has no pressure gauge you can use your thumbs; it is not accurate, but it works. Press on the side walls of the tire with your thumb to check the pressure. For a road bike, you shouldn’t be able to press into the tire while on a mountain bike tire, you should be able to push about a centimeter.

Checking the tire pressure without a gauge

When you are done pumping the tire, swiftly remove detach the pump from the valve. U may hear some air escape, which is normal. This is the air that is compressed within the hose and not from the tire. Screw back the dust cap and you are done.

However much valves are reliable, they are not perfect. With time air may leak out of the valve or you may suffer from pinpoint punctures. Before any ride, check the pressure of your tires with your thumbs.